URKI-LATEX SAT Satin Chlorinated Rubber Enamel

General Information

| Compatibility and surface | Application |

|---|---|

| Steel | Airbrush |

| Iron | Airmix |

| Airless | |

| Brush - roller |

| Quality | Gloss |

|---|---|

| 1K | Satin |

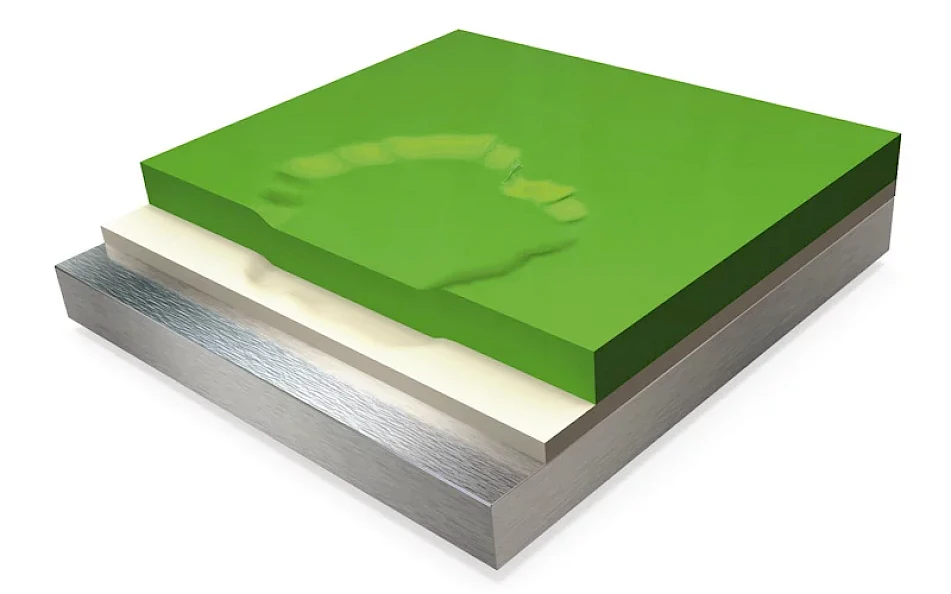

PRODUCT DESCRIPTION

"USE ONLY IN INDUSTRIAL FACILITIES"

In industrial maintenace for the protection of concrete in civil works, cement plants, cranes, containers, work booths, paper mills, coking plants, chemical industry, silos, etc. Suitable on surfaces exposed to a strong humidity, structures submerged both in sweet and salt water.

Intermediate coat for Zinc Rich Primer prior to the finishing with Chlorinated Enamel. Recommended as Satin Topcoat Enamel.

APPLICATION

25-30"

25-30"  URKISOL 222 10-20 %

URKISOL 222 10-20 %  URKISOL 170 40-50 %

URKISOL 170 40-50 %  60-80 my

60-80 my  touch Free 30 ́ Tack free 1 h.

touch Free 30 ́ Tack free 1 h.

Brush, Roller: Only for small surfaces.

DATA SHEET

PHYSICAL PROPERTIES

| Density at 20 °C (g/cc) | 1,19 - 1,30 |

| Grinding Fineness (μ) | 20 - 25 |

| Supply viscosity at 20 °C | 90 - 100 KU (Stormer) |

| % Solids content (weigth / volume) | 57 - 62 % weight; 41 - 43 % volume. |

| V.O.C. (g/l) | 510 |

| Type of product | Chlorinated Rubber |

| Color | URKI-SYSTEM |

SURFACE PREPARATION

-Steel: The surface must be throughly degreased and free from oxide, calamine or old paints. Shot blasting at Sa 2,5 is recommended. Prime with F-282/2 Zinc Phosphate Epoxi Primer or F-284/2 Rich Zinc Epoxi Primer.

-Concrete: Get rid of slack and pulverulent parts. Clean with a Hydrochloric Solution at 5 % and then rinse in water. Dry before painting.

FEATURES OF DRY FILM

| Theoretical yield (m²/l) | 5 - 6 (70 my) |

| Gloss 60° - 60° | 10 - 20 % |

| Second layer | 2-4 h. (by spray-gun) |

STORAGE

Keep under cover in a cool and well-ventilated place avoiding direct sunlight. Temperatures between 5 and 30 °C recommended.

Can life: 2 years from manufacturing in date its original unopened container. Consult our Technical Department once date has expired.

COVERAGE CALCULATOR

How much do you need?

Find out by using our Coverage Calculator

General Information

| Compatibility and surface | Application |

|---|---|

| Steel | Airbrush |

| Iron | Airmix |

| Airless | |

| Brush - roller |

| Quality | Gloss |

|---|---|

| 1K | Satin |