ALFAPUR 3791 2K Satin UHS Polyurethane Enamel

General Information

| Application | |

|---|---|

| Airbrush | |

| Airmix | |

| Airless |

| Quality | Gloss |

|---|---|

| 2K | Satin |

PRODUCT DESCRIPTION

High Solids Satin Enamel.

Indicated for the painting of machinery and industrial vehicle with Air-mix or Air-less equipment.

Elasticity, body, gloss and outdoor resistance.

APPLICATION

E-135 4:1 weight 3:1 vol.

E-135 4:1 weight 3:1 vol.  > 3 h.

> 3 h.  50-60" Air-less

50-60" Air-less  URKISOL 8229 or 3700 2-4 %

URKISOL 8229 or 3700 2-4 %  50-60 my

50-60 my  Touch Free 1 h. Tack Free 2-3 h.

Touch Free 1 h. Tack Free 2-3 h.  In cabin 15-30' 70°C/30'

In cabin 15-30' 70°C/30'

Leave the paint settle 15´ before painting.

DATA SHEET

PHYSICAL PROPERTIES

| Density at 20 °C (g/cc) | 1,18 - 1,45 |

| Grinding Fineness (μ) | 15 - 20 |

| Supply viscosity at 20 °C | 60 - 70 KU |

| % Solids content (weigth / volume) | 55 - 62 % weight; 43 - 48 % volume. (Mixture with hardener) |

| V.O.C. (g/l) | 418 (Ready to use) - (2004/42/CE) IIB (D) (420) |

| Type of produtc | Polyester - Polyurethane |

| Colour | URKI-SYSTEM |

SURFACE PREPARATION

-Steel: The surfaces to be painted, thoroughly degreased must be primed with F-296/2 or F-294/2 2K Zinc Phosphate Epoxy Primers.

For a higher rust protection, Sa 2,5 shotblasting required.

-Galvanized: Degrease. If it is old, brush and degrease. Prime with F-296/2 or F-294/2.

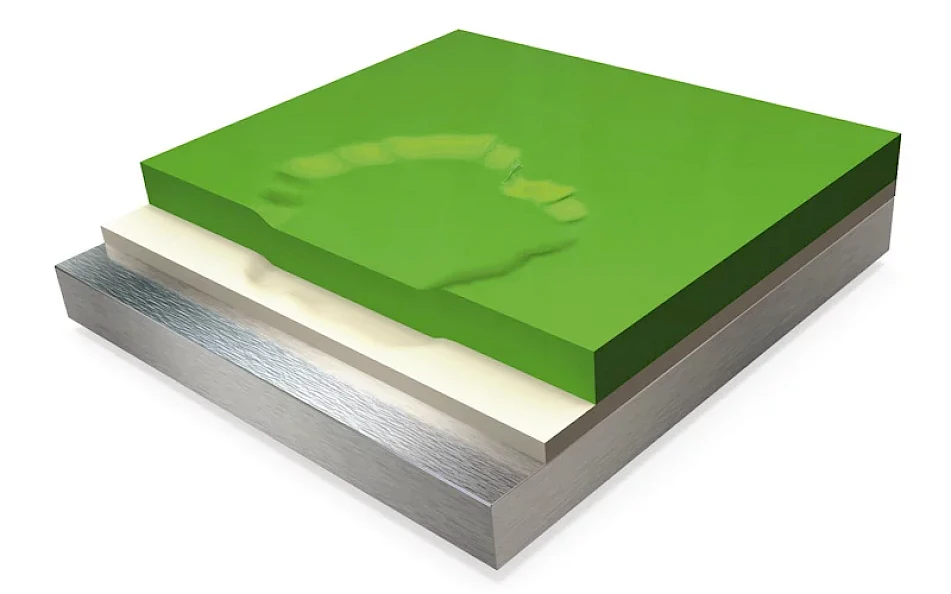

FEATURES OF DRY FILM

| Theoretical yield (m²/l) | 9 - 10 (50 my) |

| Gloss 60° - 60° | 25 - 35 % |

| Second layer | 3 h. after spray-booth drying |

STORAGE

Keep under cover in a cool and well-ventilated place avoiding direct sunlight. Temperatures between 5 and 30 °C recommended.

Can life: 2 years from manufacturing in date its original unopened container. Consult our Technical Department once date has expired.

COVERAGE CALCULATOR

How much do you need?

Find out by using our Coverage Calculator

General Information

| Application | |

|---|---|

| Airbrush | |

| Airmix | |

| Airless |

| Quality | Gloss |

|---|---|

| 2K | Satin |