URKI2000 2K Polyester Putty

DESCRIPTION

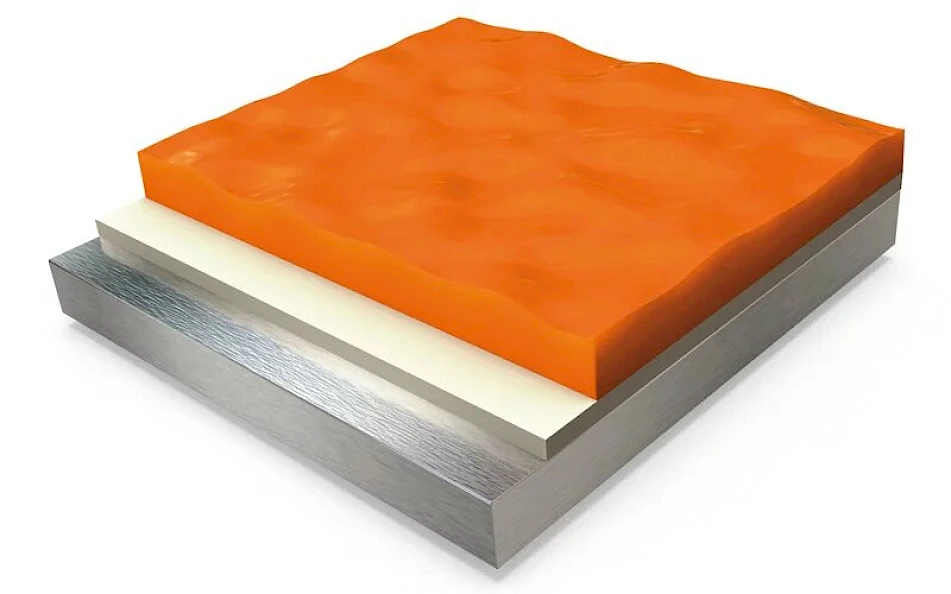

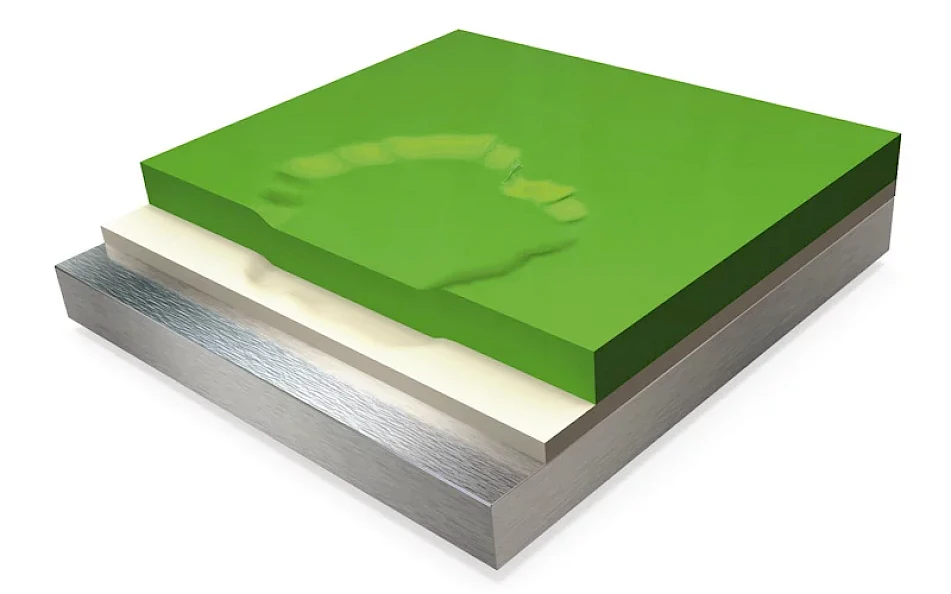

High Quality Polyester Putty designed for use in body shops, to correct defects and fill cracks or dents.

It stands out for its extraordinary easy application, fineness, sandability, absence of pores and flexibility. It adheres on sheet steel, cast iron, GRP and wood.

HARDENERS

The use of an electronic scale is recommended. Mix homogeneously to avoid the formation of air bubbles.

| Hardener | Percentage | Temperature |

|---|---|---|

| BPO | 3% | 5-10°C |

| BPO | 2% | 10-20°C |

| BPO | 1% | >20°C |

Note: Adding more hardener is not recommended in order to prevent bleedings in the paint.

APPLICATION PROCESS

APPLICATION

| BPO | ||

|---|---|---|

| Mixing ratio Weight | 100:1-3 P |

| Pot-life | 3-5’ |

| Spatula Number of coats Total thickness | Avoid air bubble formation during its application. Vary depending on the depth of the repair. 1000-3000 μm |

| Drying Time 20°C IR Medium wave | 20-30’ 5’ |

| Sanding | P120-P220 |

Application: By spatula.

The hardener mixture can be carried out on the same spatula, homogenizing it well before applying.

When a deep filling is required, apply several layers, letting them dry at each time during the process. Sanding at each stage is recommended in order to obtain better adhesion between the coats.

SURFACE PREPARATION

The surface to be repaired must be free of rust and grease, for which we recommend previous sanding (P80-P120). On electro-zinc plating better use StarBrite.

Do not use this putty on wash-primer or phosphochromatic primers. If the original paint is thermoplastic acrylic, bare metal must be reached.

For greater substrate protection, especially in steel, use first a primer from BESA’s product line such as F-286/2.

Recoatable with any Acrylic or Epoxy finish system once sealed, preferably with a 2K filler from the BESA product line.

MIXING RATIOS

| Recommended mixes | 100 g | 250 g |

|---|---|---|

| BPO mix 3% | 3 | 7,5 |

| BPO mix 2% | 2 | 5 |

| BPO mix 1% | 1 | 2,5 |

RELATED INFORMATION

SAFETY INSTRUCTIONS

The use of appropriate personal protective equipment is recommended during application, to prevent the irritation of the respiratory tract, skin and eyes. For professional use only.

STORAGE

Keep in a tightly covered container, in a dry and ventilated place, avoiding direct exposure to sunlight. Temperature above 5°C is recommended, between 15 and 30°C optimal.

VOC

The VOC content of URKI2000 is a maximum of 250 g/l in compliance with European standard 2004/42/CE IIB(B) (250) <250 g/l.