URKI-NATO C 2K UHS Acrylic Topcoat

PRODUCT DESCRIPTION

"USE ONLY IN INDUSTRIAL FACILITIES"

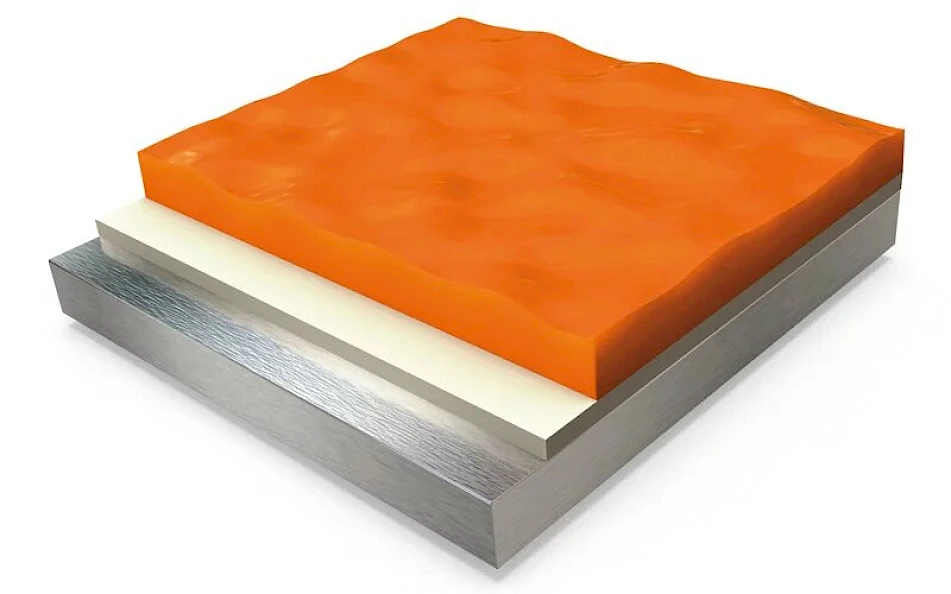

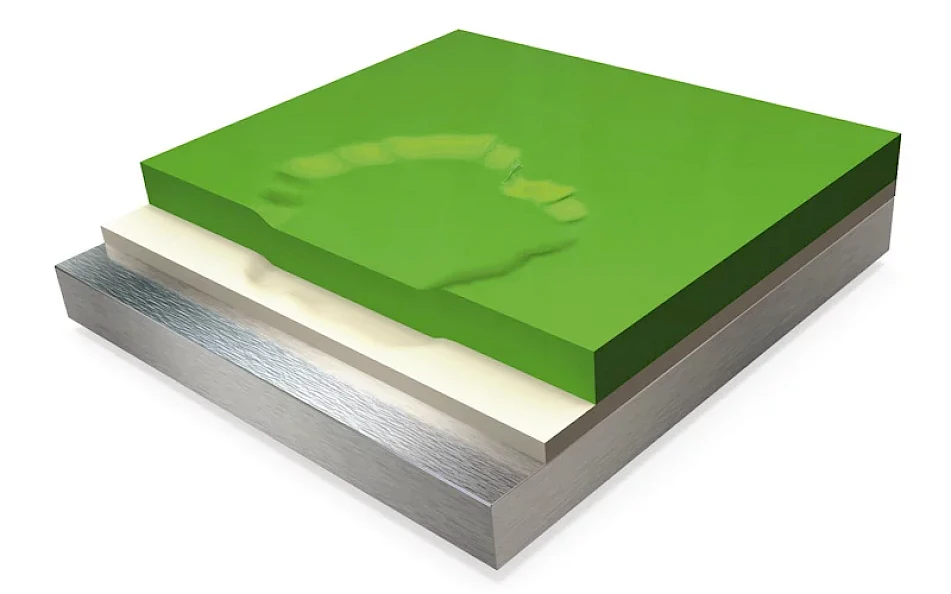

Acrylic Polyurethane Enamel with Aliphatic hardener and very solid pigments. Excellent direct adhesion, without primer, on different substrates: steel, aluminium, galvanized, PVC, etc.

Used for painting Industrial Vehicles, agricultural and public works machinery, cranes, garden furniture, PVC, PUR and ABS frames, road signs, etc.

High hardness and flexibility. Gloss and colour remain unchanged. Good outdoor resistance and suitable for medium intensity aggressive environments.

It is mainly used as a single coat, thanks to its direct adhesion.

Fulfils the UNE 135331:2004 norm (Coating of vertical road signs).

IMPLEMENTATION PROCESS

USE

| ||||

| Relación mezcla Volumen | (1) E-225 5:1 vol. | ||

| Pot-life | > 3 h. | ||

| Viscosidad de aplicación % Dilución | 20-30" | ||

| Pistola de gravedad Presión de aplicación | URKISOL 900P/8229/3700 15-20 % Ø 1.4-1.6 mm | ||

| Número de manos Espesor total | 35-50 my | ||

| Tiempo de evaporación | 10-15' | ||

| Tiempo de Secado 20°C | Non sticky 3-4 h. 60 °C/30' 70 °C/20' 110 °C/20' | ||

| 15' | |||

| URKISOL 900P/8229/3700 10-15 % 0,009-0,011" | |||

| URKISOL 900P/8229/3700 10-15 % 0,009-0,011" | |||

To apply with electrostatic equipment consult our technicians for the recommended Thinner.

SURFACE PREPARATION

Steel: degreased or phosphatised. When using a primer, previous sand-blasted Sa 2 ½ is recommended for a higher protection.

The surfaces must be free of rust, grease or dirt.

On old galvanized: brush and degrease.

On plastics: clean with thinner n.° 94. On PVC, use URKISOL 88, as a degreaser.

PHYSICAL PROPERTIES

| Density at 20 °C (g/cc) | 1,00 - 1,30 |

| Grinding Fineness (μ) | 5 - 10 |

| Supply viscosity at 20 °C | 80 - 120 sec. Ford n.° 4 |

| % Solids content (weigth / volume) | 50-60 % weight; 40-45 % vol. (Mixed with hardener) |

| V.O.C. (g/l) | 578 (Ready to use) |

| Type of produtc | Acrylic Polyurethane |

| Colour | RAL, UNE, NCS, BS, etc. |

FEATURES OF DRY FILM

| Substrate and material pretreatment | Degrease or phospatized steel, Aluminium, Galvanized |

| Mechanical properties | 7 days (on degreased steel) |

| Hardness Persoz | > 150 seg. |

| Erichsen test mm. | > 5 mm. |

| Impact D/I | 70 cm. D / 20 cm I (20 ø) |

| Doblado Mandrel bend | 6 mm ø |

| Adhesion | Gt- 0 on all the above mentioned surfaces |

| Theoretical yield (m2/l) | 9,5 - 10 (45 my) |

| Gloss 60° - 60° | > 80 % |

| Second layer | 24 h. |

RESISTANCES

| Resistance according to ISO 12944-2 | C3 HIGH C5-M HIGH (1) |

| Salt Spray Test Resistance | 500 h. (directly on Galvanized) |

| Accelerated weathering Test (1) | QUV 500 h. (2) |

| Resistance to liquids | Water, soaps, grease and oil, petrol, etc. |

(1)

C3 HIGH on F-29, F-350/2 or F-375/2

C5 M HIGH on ALFA-ZINC 1674 EZ + F-350/2 or ALFA-POX 2665 CG

(2) Cycle:

4 h. Ultraviolet 60°C

4 h. Condensation 50°C

Lamp of type B

INFORMACIÓN RELACIONADA

STORAGE

Keep under cover in a cool and well-ventilated place avoiding direct sunlight. Temperatures between 5 and 30 °C recommended.

Can life: 2 years from manufacturing in date its original unopened container. Consult our Technical Department once date has expired.