BESA-NATO SAT 2K DTM Acrylic Satin Enamel

General Information

| Compatibility and surface | Application |

|---|---|

| Steel | Airbrush |

| Stainless steel | Airmix |

| Aluminum | Airless |

| Galvanized | |

| Iron | |

| PVC | |

| ABS Plastic | |

| GRP | |

| Glass | |

| PUR | |

| Ceramics | |

| PC | |

| MA | |

| Brass |

| Quality | Gloss |

|---|---|

| 2K | Satin |

PRODUCT DESCRIPTION

"USE ONLY IN INDUSTRIAL FACILITIES"

Satin enamel, does not yellow. Good physicochemical resistance and direct adhesion on many surfaces: Steel, Stainless Steel, Aluminium, Brass, Galvanized, Glass, Plastics ABS, PUR, PC, MA, GRP, Ceramic, PVC.

Up to 200 hours in the Salt Spray Test on Shotblasted Steel.

APPLICATION

E-224 (*) 3:1 vol.

E-224 (*) 3:1 vol.  3 h.

3 h.  20-30"

20-30"  URKISOL 8229/900P 5-10 % vol.

URKISOL 8229/900P 5-10 % vol.  40-50 my

40-50 my  Air: Non Sticky 3-4 h.

Air: Non Sticky 3-4 h.  10-15' Cabin: 70°C/30'

10-15' Cabin: 70°C/30'  20'

20'  URKISOL 8229 10-15% 0,009-0,011"

URKISOL 8229 10-15% 0,009-0,011"  URKISOL 8229 5-10% 0,009-0,011"

URKISOL 8229 5-10% 0,009-0,011"

Aerographic application: Dilute with thinner URKISOL 8229 or URKISOL 900/P.

In summer or warm days, to use URKISOL 3700.

Leave paint settle 15 minutes before painting.

For application with airmix equipment, with no dilution, viscosity of mixture with hardener.

We can achieve a range of middle gloss by mixture with BESA-NATO binders, maintainig always the mixture hardener 3:1 vol.

DATA SHEET

PHYSICAL PROPERTIES

| Density at 20 °C (g/cc) | 1,00 - 1,25 |

| Grinding Fineness (μ) | 5 - 10 |

| Supply viscosity at 20 °C | 65 - 75 KU (Stormer) |

| % Solids content (weigth / volume) | 50 - 60 % weight; 40 - 50 % volume. (Mixture with hardener) |

| V.O.C. (g/l) | 548 (Ready to use) |

| Type of product | Acrylic Polyurethane Aliphatic |

| Colour | URKI-SYSTEM |

SURFACE PREPARATION

The surface must be free of rust, grease and dirt.

Galvanized: If old, brush and degrease.

On Plastics clean with URKISOL 94 in case of PVC, degrease with URKISOL 88.

On powder coatings and coal coatings, a previous sanding is recommended. After it, degrease with URKISOL 300. Depending on the type and conditions of the support.

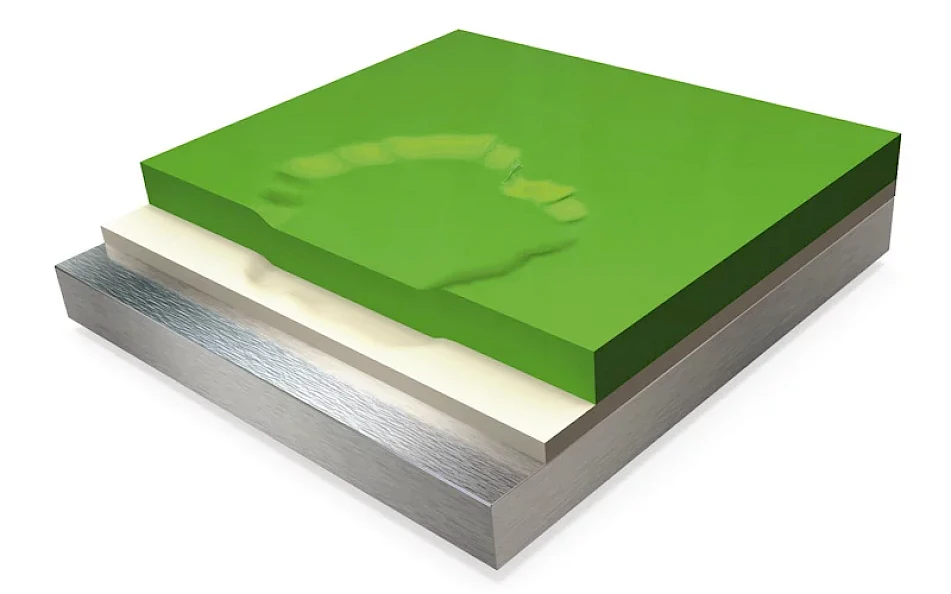

FEATURES OF DRY FILM

| Theoretical yield (m²/l) | 8 - 10 (45 my) |

| Gloss 60° - 60° | 10 - 30 % |

| Second layer | 18 h. |

| BESA-NATO SAT | 55 | 90 | 80 | 70 | 60 | 50 |

| BESA-NATO | - | 10 | 20 | 30 | 40 | 50 |

| F-755 | 45 | - | - | - | - | - |

| Gloss 60° - 60° | <15 | 25-35 | 30-45 | 45-60 | 60-70 | 70-80 |

The values shown in the table are for guidance only.

As accelerator use E-745 (do not use hardener E-202 or accelerator E-750).

STORAGE

Keep under cover in a cool and well-ventilated place avoiding direct sunlight. Temperatures between 5 and 30 °C recommended.

Can life: 2 years from manufacturing in date its original unopened container. Consult our Technical Department once date has expired.

COVERAGE CALCULATOR

How much do you need?

Find out by using our Coverage Calculator

General Information

| Compatibility and surface | Application |

|---|---|

| Steel | Airbrush |

| Stainless steel | Airmix |

| Aluminum | Airless |

| Galvanized | |

| Iron | |

| PVC | |

| ABS Plastic | |

| GRP | |

| Glass | |

| PUR | |

| Ceramics | |

| PC | |

| MA | |

| Brass |

| Quality | Gloss |

|---|---|

| 2K | Satin |