F-3195/2 2K Epoxy-Tar Paint

Colors

General Information

| Compatibility and surface | Application |

|---|---|

| Shotblasted steel | Airbrush |

| Airmix | |

| Airless | |

| Brush - roller |

| Quality | Gloss |

|---|---|

| 2K | Satin |

Can size

- 15L 1 Pcs x box

PRODUCT DESCRIPTION

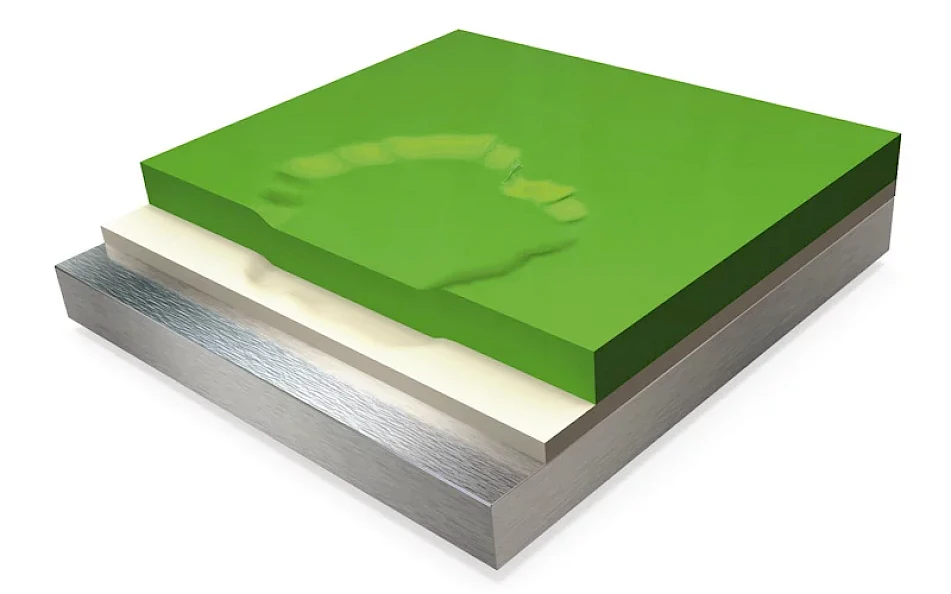

High-protection paint based on Coal Tar and Epoxy Resin hardened with Polyamide. Aimed protection of Steel and Concrete in a maritime environment, corrosive atmospheres, underground structures such as tanks for crude oil, fuel-oil, ballast water, residual water installations, underwater bodies of vessels, water locks, rig equipment, etc.

Not recommended for contact with aromatic hydrocarbons, esters, Ketones, Strong Oxidant Acids.

APPLICATION

E-90 3:1

E-90 3:1  24 h.

24 h.  75-80 KU Air-less

75-80 KU Air-less  URKISOL 170 5-8 % 100-200 my

URKISOL 170 5-8 % 100-200 my  URKISOL 222 For touching up

URKISOL 222 For touching up  Touch free 1 h. Tack free 24 h.

Touch free 1 h. Tack free 24 h.

Application with Air-less equipment; to obtain 100 to 200 my per coating.

On concrete 2 coatings of 200 my each with an titerval of 24 hours are given.

DATA SHEET

PHYSICAL PROPERTIES

| Density at 20 °C (g/cc) | 1,30 ± 0,03 |

| Grinding Fineness (μ) | |

| Supply viscosity at 20 °C | 100 - 110 KU Stormer |

| % Solids content (weigth / volume) | 70 % ± 2 weight; 56 % ± 2 volume. (Mixture with hardener) |

| V.O.C. (g/l) | < 420 (Ready to use) - (2004/42/CE) IIA (j) (500) |

| Type of produtc | Tar-Epoxy / Polyamide |

| Colour | Black |

SURFACE PREPARATION

Steel surfaces: Must be sand-blasted first at grade Sa 2,5.

On concrete: Remove dirt and grease.

In order to guarantee a better anti-corrosive protection, the first coat may be substituted by Primers F-284/2, F-294/2, F-296/2 or F-282/2.

FEATURES OF DRY FILM

| Theoretical yield (m2/l) | 3,5 (150 my) |

| Gloss 60° - 60° | Satin |

| Second layer | 24 h. |

STORAGE

Keep under cover in a cool and well-ventilated place avoiding direct sunlight. Temperatures between 5 and 30 °C recommended.

Can life: 2 years from manufacturing in date its original unopened container. Consult our Technical Department once date has expired.

COVERAGE CALCULATOR

How much do you need?

Find out by using our Coverage Calculator

Colors

General Information

| Compatibility and surface | Application |

|---|---|

| Shotblasted steel | Airbrush |

| Airmix | |

| Airless | |

| Brush - roller |

| Quality | Gloss |

|---|---|

| 2K | Satin |

Can size

- 15L 1 Pcs x box