ALFAZINC 1674 EZ 2K Zinc-Rich Epoxy Primer

Colors

General Information

| Compatibility and surface | Application |

|---|---|

| Shotblasted steel | Airbrush |

| Airmix | |

| Airless | |

| Brush - roller |

| Quality | Gloss |

|---|---|

| 2K | Matt |

Can size

- 5,5L 1 Pcs x box

PRODUCT DESCRIPTION

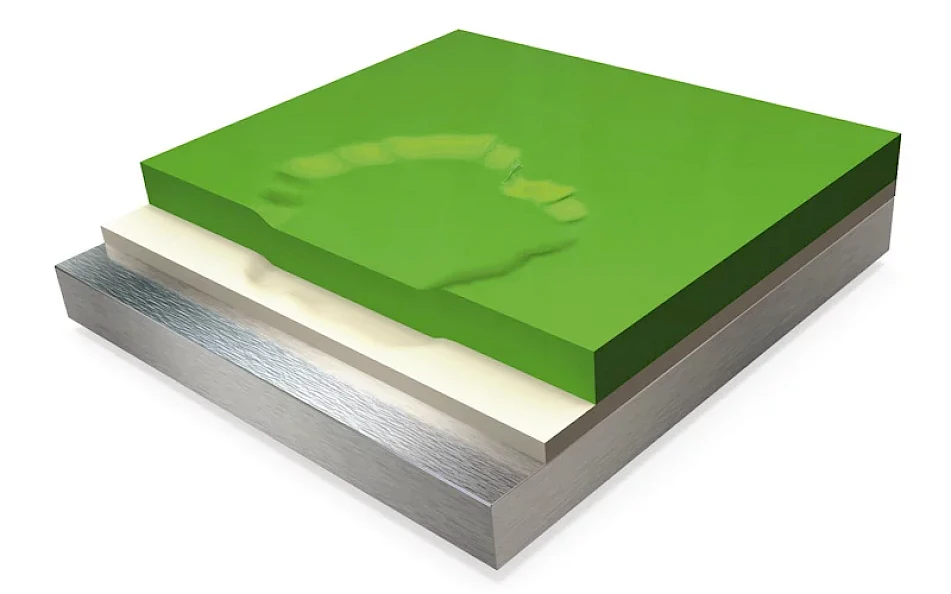

2K epoxy polyamide anticorrosion primer with high percentage in metal zinc.

Steel protection on aggressive environments: boilermaking, sewage treatment plants, chemical and paper industry, thermal power stations, etc.

Excellent application properties, resistance to abrasion and rust protection. Quick drying. Recoatable with a wide range of products: chlorinated rubber, vynil, epoxy, acrylics, polyurethanes, etc. once recoated with an intermediate coat.

ALFA- ZINC 1674 is part of the recommended process to achieve C5 I High in high resistance Marine and Industrial environments according to UNE EN ISO 12944-2 (See Guide to Industrial Paint).

APPLICATION

E-305 5,5:1 vol / 94:6 weight

E-305 5,5:1 vol / 94:6 weight  8 h.

8 h.  Spraygun 20-30" Air-less 30-35"

Spraygun 20-30" Air-less 30-35"  URKISOL 357 15-20 % 1,6-1,8 mm. ø

URKISOL 357 15-20 % 1,6-1,8 mm. ø  50-60 my

50-60 my  3h. Tack free

3h. Tack free  URKISOL 357 15-20% 0,013-0,015"

URKISOL 357 15-20% 0,013-0,015"  Without thinner (Small repair or touch up)

Without thinner (Small repair or touch up)

APPLICATION MODE

Thorough mechanical homogeneization of the pigmented liquid component, slowly adding the hardener while mixing and diluting at the same time. Partial mixtures are not recommended. Recoat with intermediate coats such as F- 294/ 2, F- 296/ 2, F- 350/ 2, F- 386/ 2, etc.

Do not paint if the ambient temperature is below 10°C and the surface is not at least 3°C above the dew point.

DATA SHEET

PHYSICAL PROPERTIES

| Density at 20°C (g/cc) | 2,55 ± 0,03 |

| Grinding Fineness (μ) | Without Lumps |

| Supply viscosity at 20°C | 110 - 120 KU (Stormer) |

| % Solids content (weigth / volume) | 82% ± 2 weight; 53% ± 2 vol. |

| VOC (g/l) | 476 (Ready to use) - (2004/42/CE) IIA (j) (500) |

| Type of product | Epoxy - Polyamide |

| Color | 7000 Grey |

SURFACE PREPARATION

Cleaning thinner: URKISOL 700 E, URKISOL 200 o P-1.

Shotblasting to Sa 2½necessary from the Swedish Norm SIS 05 59 00, with profile from 25 to 50 microns.

The surface must be clean, dry and free from grease, oil, or seal spikes, etc.

FEATURES OF DRY FILM

| Theoretical yield (m2/l) | 9-9,5 (55 µm) |

| Gloss 60° - 60° | Matt |

| Second layer | Minimum: 1 hour; Maximum: No limit |

RESISTANCES

| Max. continuous temperature exposure | 125°C |

| Resistance according to ISO 12944-2 | Resistance according to ISO 12944-2. C5 I High (recoated with F- 294/ 2 and URKI- NATO. Certified by a homologated external laboratory). |

STORAGE

Keep under cover in a cool and well-ventilated place avoiding direct sunlight. Temperatures between 5 and 30 °C recommended.

Can life: 6 months from manufacturing in date its original unopened container. Consult our Technical Department once date has expired.

REMARKS

Do not expose to acid or alkaline environments, without recoating with an Epoxy Intermediate Coat.

Not indicated for surfaces to be placed under water, not even when recoated with multicoat processes.

If the product has been exposed for a long time outdoors and first white stains appear (salt or Zinc oxids), clean thoroughly with high pressure drinking water and scrub with bristle brush.

COVERAGE CALCULATOR

How much do you need?

Find out by using our Coverage Calculator

Colors

General Information

| Compatibility and surface | Application |

|---|---|

| Shotblasted steel | Airbrush |

| Airmix | |

| Airless | |

| Brush - roller |

| Quality | Gloss |

|---|---|

| 2K | Matt |

Can size

- 5,5L 1 Pcs x box